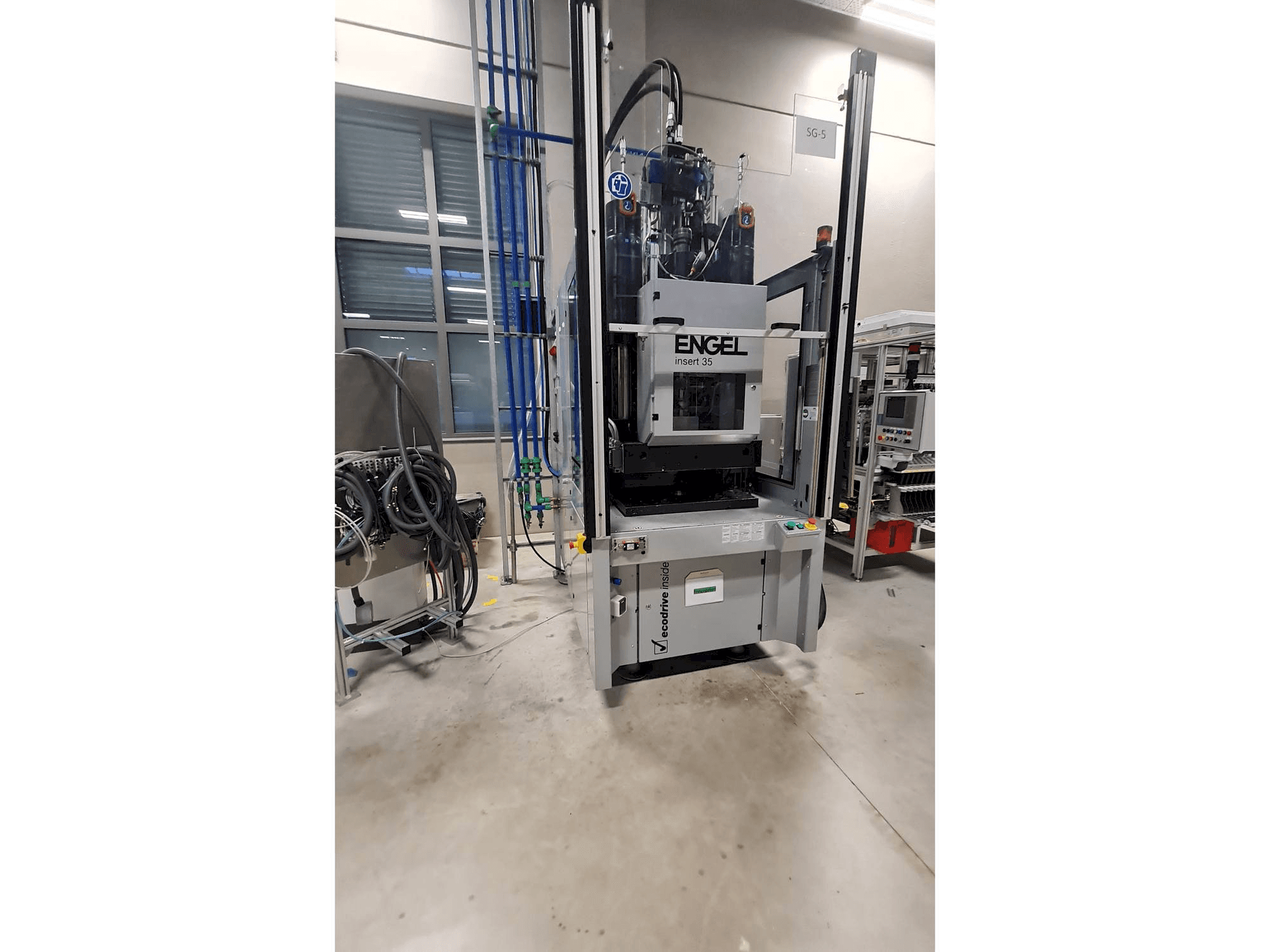

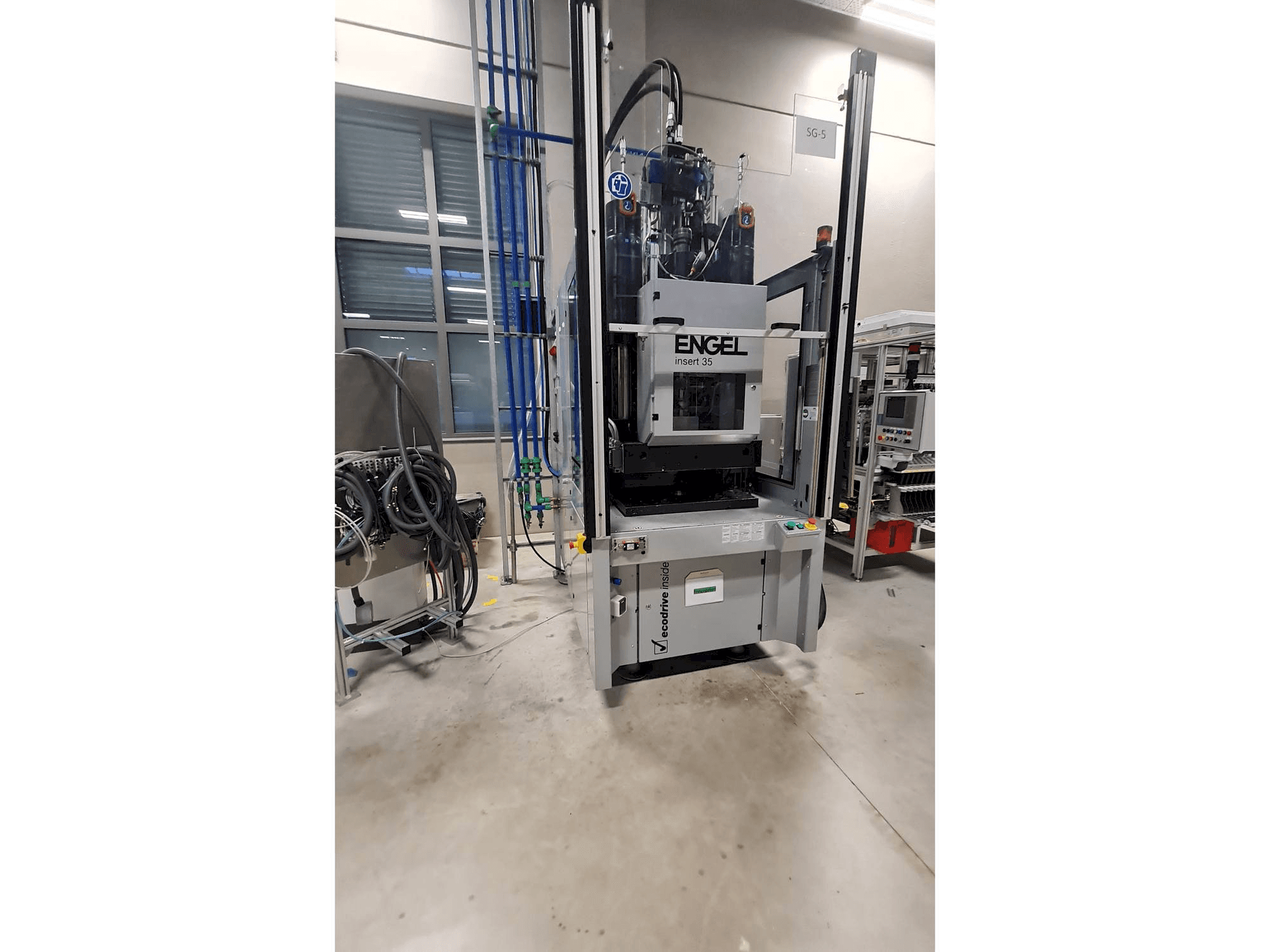

Engel - insert 60V-35 single XS ecodriveDE-INJ-ENG-2017-00001

£ 19,144

gindumac price

(Ex works)

get an official quote

Visit the machine

make a counteroffer

Download PDF

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

Click to chat on WhatsApp

- GINDUMAC

- Products

- Plastics Processing Machinery

- ENGEL insert 60V-35 single XS ecodrive Injection moulding machine

Show in original language

This ENGEL insert 60V-35 single XS ecodrive Injection moulding machine was manufactured in the year 2017 in Austria and has 12750 production hours. It is equipped with an Engel CC300 control unit. The machine has a clamping force of 350 kN. 3 units are available.

Overview

- brand: Engel

- year: 2017

- MODEL: insert 60V-35 single XS ecodrive

- production hours: 12750

- application type: Injection Moulding

- Location: Germany

- machine type: Vertical Injection Moulding Machine

- control unit brand: ENGEL

Technical Information - Engel insert 60V-35 single XS ecodrive

Control Unit

- Control Brand: ENGEL

- Control Model: CC300

Dimensions

- Machine Depth: 2600 mm

- Machine Height: 1400 mm

- Machine Weight: 4450 kg

Technical Specification

- Clamping Force: 350 kN

- Screw Diameter: 15 mm

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Your account manager:

Borja Garcia

Borja Garcia is one of our used machinery trading experts and will be your direct contact for any further questions on the machine. Feel free to contact him/her.

Payment Terms

Payment in advance

Asset Financing