Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

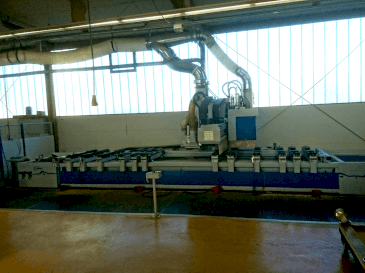

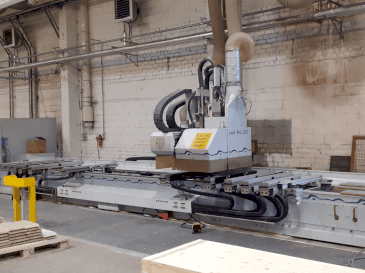

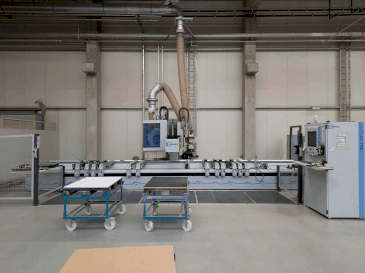

HOMAG - OPTIMAT BAZ222/60/KDE-WOO-HOM-2010-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used HOMAG OPTIMAT BAZ222/60/K - For Sale

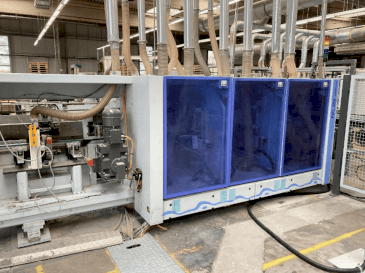

This CNC processing centre was manufactured in 2010. It features a main spindle of 15 KW with HSK F63, an 18-fold plate changer, and a 30-spindle drilling head. Equipped with a POWER EDGE gluing unit for precise edge banding and a FLEX-5 unit for enhanced versatility. Ideal for handling large workpieces with a maximum thickness of 300 mm. For more information about this woodworking processing centre, please reach out to us.

Overview

- brand: HOMAG

- year: 2010

- MODEL: OPTIMAT BAZ222/60/K

- application type: CNC Wood Machining

- Location: Germany

- machine type: CNC Processing Center

Technical Information - HOMAG OPTIMAT BAZ222/60/K

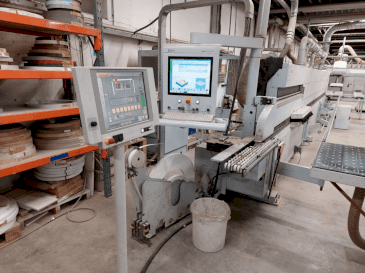

Control Unit

- Model: OPTIMAT BAZ222/60/K

Additional Information

Additional equipment

- Gluing unit with FLEX-5 unit

- Main spindle 15 KW, HSK F63

- C-Axis with unit interface

- Plate changer 18-fold D=130

- Drilling head 30 spindles: V20 / H10/ S360° "MPU"

- Groove saw: blade-Ø: 200 mm

- Adaptive milling spindle 6 KW for drilling head

- Gluing unit POWER EDGE for 360°-gluing with butt joint

- Flush milling unit for tool changer

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to HOMAG OPTIMAT BAZ222/60/K

Optimat BHC 655

Weeke - CNC Router

Profi BHC 600

Weeke - CNC Router

4121 PRO EVO

INFOTEC - CNC Router

Speed-Cut SC1

HUNDEGGER - CNC Wood Machining Centre

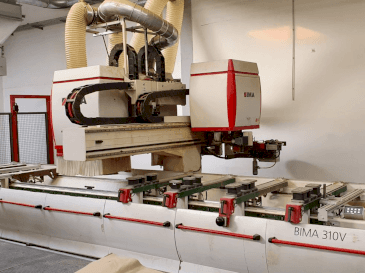

BIMA 310V 120/600

IMA - CNC Wood Machining Centre

OPTIMAT BAZ222/60/K

HOMAG - CNC Processing Center

BIMA/410/120/600

IMA - CNC Wood Machining Centre

Optimat BP145

Weeke - CNC Processing Center

PROFI FPL 525/6/04/PW/V LVT Profiling System

HOMAG - Profile Bending Machine

SPRAYTEQ S-100

HOMAG - Other (Wood)

KAL 330/9/A6/L

HOMAG - Edgebander

FPM 470

MAKA - CNC Wood Machining Centre