Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

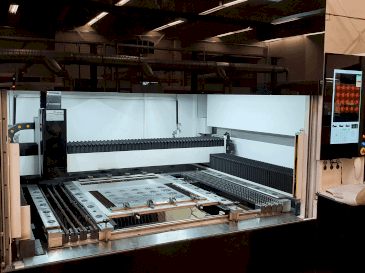

TRUMPF - TruLaser 5040 + LiftmasterDE-LAS-TRU-2007-00003

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- TRUMPF TruLaser 5040 + Liftmaster Laser Cutting machine

This TRUMPF TruLaser 5040 + Liftmaster Laser Cutting machine was made in 2007. It is equipped with a SIEMENS SINUMERIK 840D control unit. The machine has a laser power of 5,0 kW.

Overview

- brand: TRUMPF

- year: 2007

- MODEL: TruLaser 5040 + Liftmaster

- application type: Cutting

- Location: Germany

- machine type: CO2 Laser Cutting Machine

- control unit brand: SIEMENS

Technical Information - TRUMPF TruLaser 5040 + Liftmaster

Control Unit

- Model: Sinumerik 840D

- Brand: SIEMENS

Main drive

- Laserpower: 5,0 kW

Workpiece

- Workpiece x: 4000 mm

- Workpiece y: 2000 mm

- Workpiece z: 110 mm

Additional Information

- Technical Machine Benefits:

- - Software licence is included

- - Fast processing with sprintline in all sheet thicknesses, programmable power cycles

- - Contourline for the production of small holes

- - Pierceline

- - Spraying device for safe thick sheet processing

- - Automatic sheet metal outer edge detection

- - Safety: multi-beam light barriers, beam guidance

- - Nitroline high-pressure cutting

- - Automatic focus position adjustment focusline - laser power control

- - Position laser diode

- Qualitative Machine Benefits:

- - Cutting gas pressure setting programmable

- - Controlline capacitive height control and process control

- - Laser cutting head with 7. 5" lens and laser cutting head with 10" lens for truflow 6000

- - Laser cutting head with 5" lens and laser cutting head with 7. 5" lens for truflow 5oo0

- - Cutting head quick-change device

- - Drives: gantry drive in combination with linear drives direct drives

- - Automatic pallet changer

- - Closed machine frame with integrated laser unit - laser unit: truflow 5000 high-frequency excited co2 laser, maintenance-free turbo radial fan, cooling unit, logbook function

- - Fully encapsulated and ventilated with nitrogen,

- - Longitudinal conveyor belt for small parts/waste

Machine Benefits

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to TRUMPF TruLaser 5040 + Liftmaster

Platino Fiber

Prima Power - Fiber Laser Cutting Machine

TrumaBend V85S

TRUMPF - Press Brake

CP 4000 Zaphiro

Prima Power - CO2 Laser Cutting Machine

Trupunch 5000

TRUMPF - CNC Punch Press

MERCURY 603 1520 350W

SEI - CO2 Laser Cutting Machine

Trumatic 5000 R

TRUMPF - CNC Punch Press

Loadmaster

TRUMPF - Automation System

primus 322

Intermac - Waterjet Cutting Machine

HD-F 3015

Durma - Fiber Laser Cutting Machine

MSF 9001.25Lr+T500 (2015)

MicroStep - Fiber Laser Cutting Machine

PLATINO FIBER

Prima Power - Fiber Laser Cutting Machine

i5

Bodor - Fiber Laser Cutting Machine