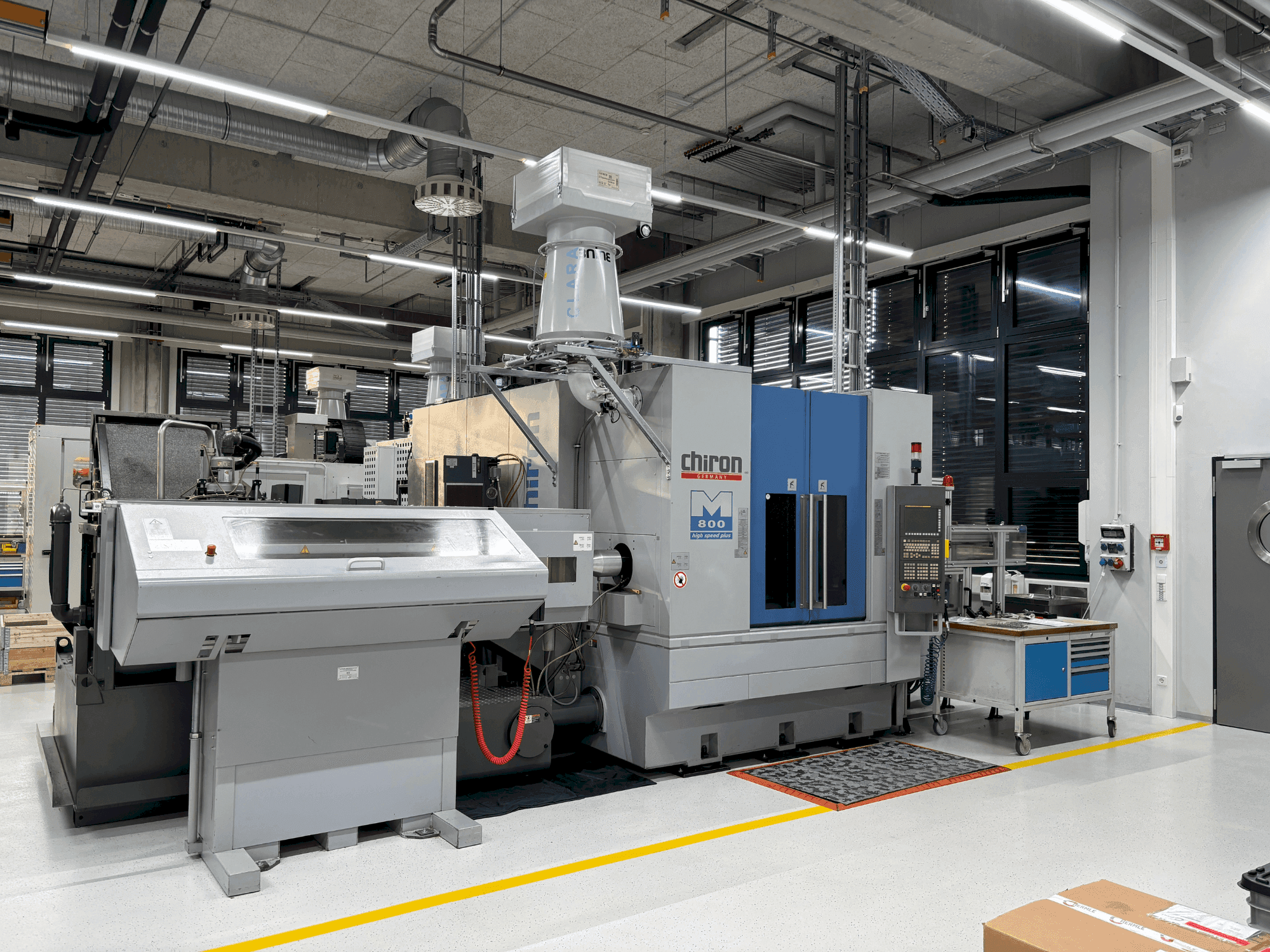

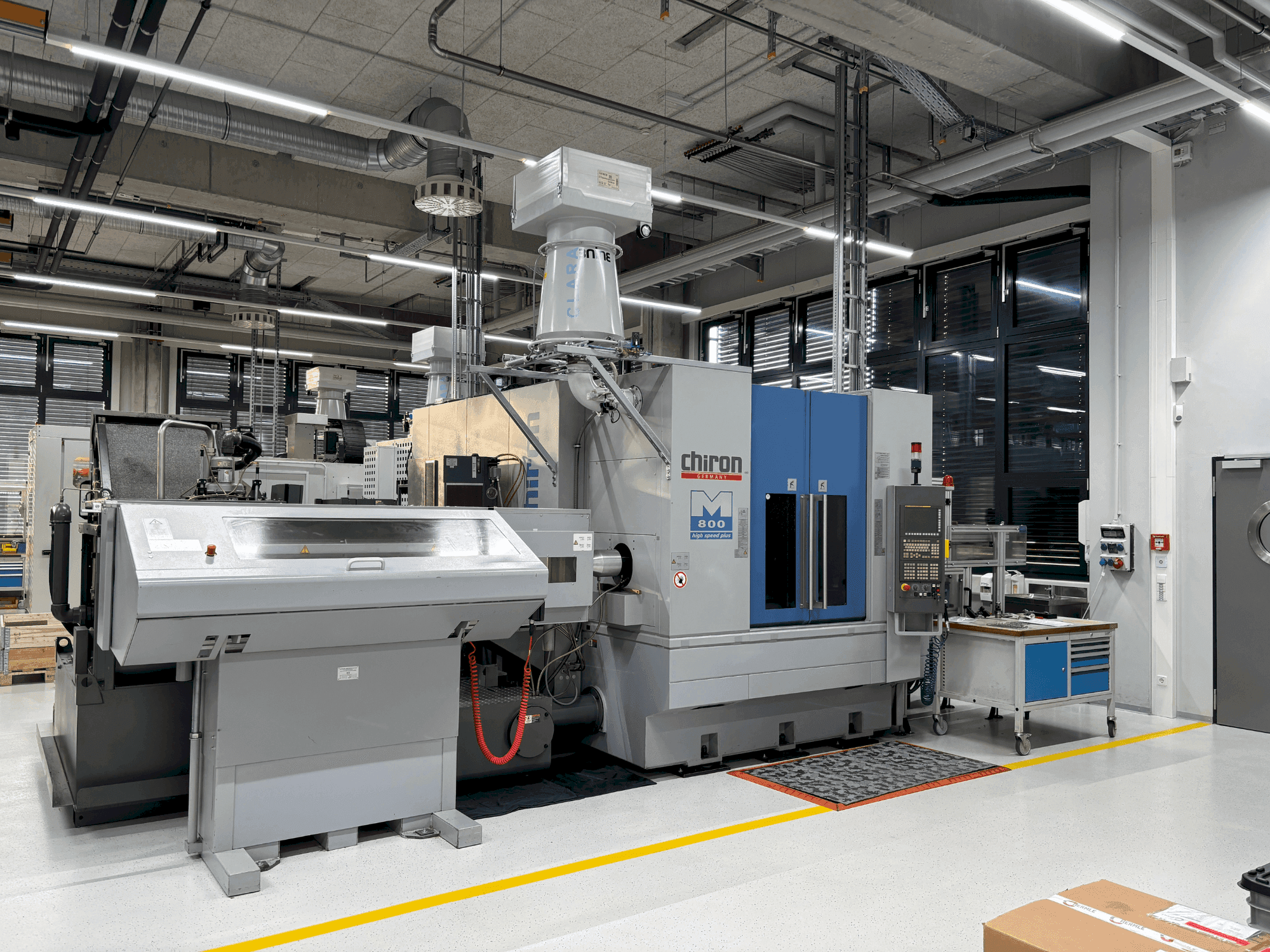

CHIRON - Mill 800DE-MIL-CHI-2007-00004

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used CHIRON Mill 800 For Sale | gindumac.com

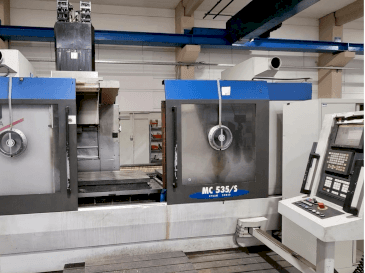

This 5-axis CHIRON Mill 800 was manufactured in 2007, featuring a swivel head, bar loader, internal cooling, and a Knoll paper belt chip conveyor. Equipped with a Fanuc 310i-model A5 and HSK-a-63, it includes about 20 tool holders. Consider the opportunity to buy this CHIRON Mill 800 turn-mill centre. Contact us for more information about this machine.

Overview

- brand: CHIRON

- year: 2007

- MODEL: Mill 800

- application type: Milling

- Location: Germany

- machine type: Mill-Turn Centre

- control unit brand: FANUC

Technical Information - CHIRON Mill 800

Control Unit

- Brand: FANUC

- Model: 18i MB5

Movement

- X-AXIS Movement: 800 MM

- Y-AXIS Movement: 500 MM

- Z-AXIS Movement: 550 MM

Additional Information

Additional equipment

- Approx. 20 tool holders included

- Bar loader short

- Knoll paper belt chip conveyor HL450/900

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to CHIRON Mill 800

GX 600

Bridgeport - Vertical Machining Centre

TC 32B

Brother - Vertical Machining Centre

HS500i

HYUNDAI KIA - Horizontal Machining Centre

F5

Makino - Vertical Machining Centre

MTV 655/60N

Mazak - Vertical Machining Centre

DECKEL MAHO DMC 60H Linear

DMG - Horizontal Machining Centre

NHP 5000

DN SOLUTIONS - Horizontal Machining Centre

UMC-500SS

HAAS - Universal Machining Centre

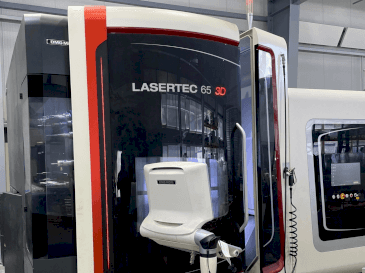

LASERTEC 65 3D Hybrid

DMG MORI - Universal Machining Centre

TM 2

HAAS - Vertical Machining Centre

Robodrill D21MiA5

FANUC - Vertical Machining Centre

MC 535

STAMA - Vertical Machining Centre