Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

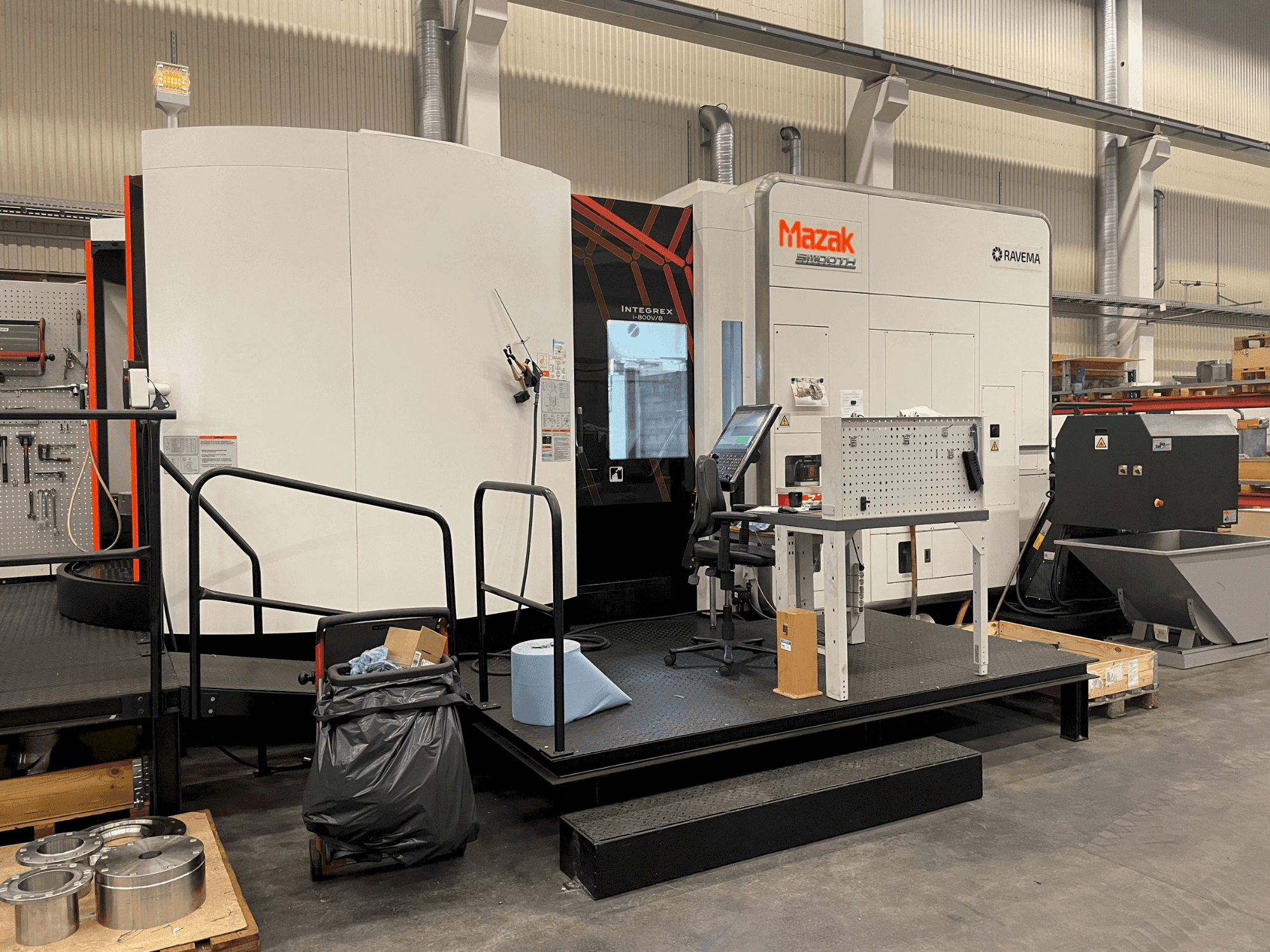

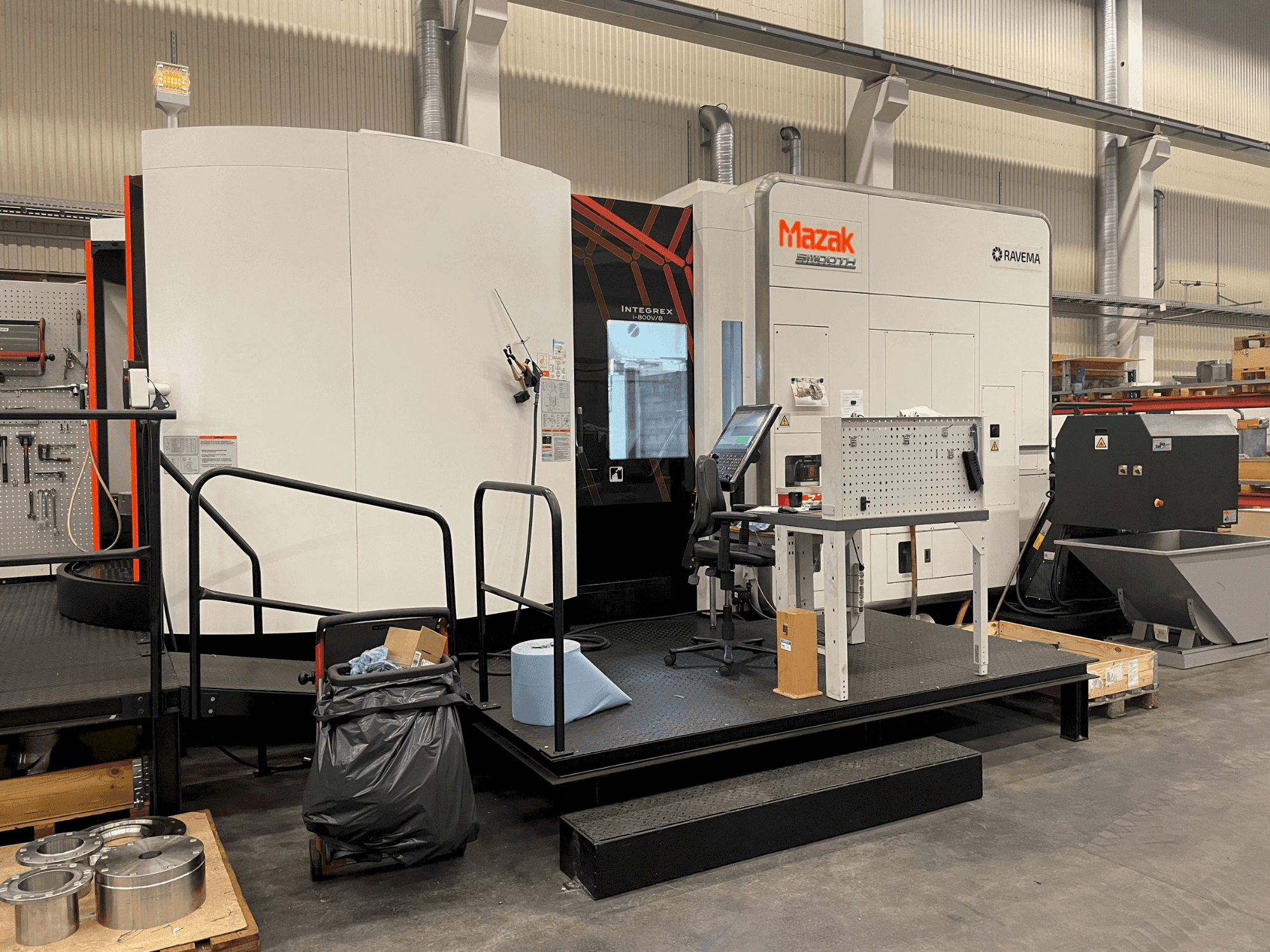

Mazak - INTEGREX i-800V/8SE-MIL-MAZ-2017-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- MAZAK INTEGREX i-800V/8 (2017) 5-Axis Universal Machining Centre

This MAZAK INTEGREX i-800V/8 (2017) 5-Axis Universal Machining Centre (Turn-Mill) was manufactured in 2017 in Japan. It is equipped with a high torque milling spindle with scale feedback (max. 5.000 rpm), a 80x tool magazine (capto), MAZAK tool identification system and multi tool function. The machine has 5 axis machining package for SmoothX (X-axis stroke: 1.700mm / Y-axis stroke: 1.500mm / Z-axis stroke: 1.150mm / B-axis: 150° (-30°, +120°) / C-axis: 360°), operates with a max. machining diameter of 1,500 mm and a table speed of 500 rpm. It comes with a RENISHAW RMP 600 probe, laser tool measurement, coolant temperature control system, blowing air through coolant, large volume coolant option and chip conveyor (rear, right). The cutting time is at 3539 hours. This INTEGREX i-800V/8 Multi-Tasking machine combines full 5-axis milling and powerful turning operations to productively process large, highly complex parts such as jet engine components and spiral bevel ring gears. As machine is still under power it can be inspected at any time. See video gallery for more impressions.

Overview

- brand: Mazak

- year: 2017

- MODEL: INTEGREX i-800V/8

- production hours: 3539

- application type: Milling

- Location: Sweden

- machine type: Universal Machining Centre

Technical Information - Mazak INTEGREX i-800V/8

Main drive

- Spindle speed range: 5000 1/MIN

- Tool taper: CAPTO

- Number of axis: 5

Movement

- X-AXIS Movement: 1700 MM

- Y-AXIS Movement: 1500 MM

- Z-AXIS Movement: 1150 MM

- B-AXIS Movement: 150° (-30°, +120°)

- C-AXIS Movement: 360°

Tools

- Slots in storage: 80

- Type of tool holder: CAPTO

Media

- Chip conveyor: Yes

Additional Information

Additional equipment

- Renishaw RMP 600

- Chip conveyor (rear/right)

- Superflow V30C-J

- Extractor GP3000

- Laser tool measurement

- Coolant temperature control system

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to Mazak INTEGREX i-800V/8

GX 600

Bridgeport - Vertical Machining Centre

TC 32B

Brother - Vertical Machining Centre

HS500i

HYUNDAI KIA - Horizontal Machining Centre

F5

Makino - Vertical Machining Centre

MTV 655/60N

Mazak - Vertical Machining Centre

DECKEL MAHO DMC 60H Linear

DMG - Horizontal Machining Centre

NHP 5000

DN SOLUTIONS - Horizontal Machining Centre

UMC-500SS

HAAS - Universal Machining Centre

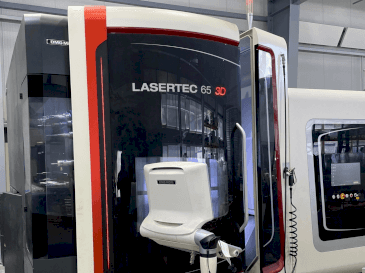

LASERTEC 65 3D Hybrid

DMG MORI - Universal Machining Centre

TM 2

HAAS - Vertical Machining Centre

Robodrill D21MiA5

FANUC - Vertical Machining Centre

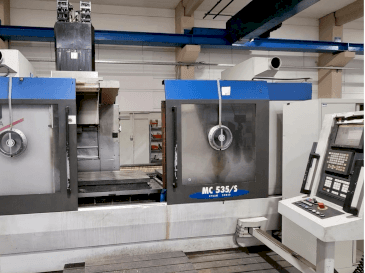

MC 535

STAMA - Vertical Machining Centre